Restaurant Inventory Management: Save Costs and Reduce Waste

“If food waste were a country, it would be the third-largest emitter of greenhouse gasses (GHGs) globally (8–10% of global emissions), after the US and China”.

Capgemini Research Institute, 2022

What is a Restaurant Inventory Management

Restaurant inventory management is the process F&B businesses use to track and control ingredients, supplies, and materials that they use to ensure optimal stock levels. It involves monitoring the amount of inventory on hand, recording usage, ordering new supplies, and minimizing waste.

Effective inventory management helps restaurants:

- Avoid overstocking or understocking, ensuring ingredients are fresh and not wasted.

- Reduce food costs by identifying areas of waste or overuse.

- Improve profitability by optimizing purchasing and usage.

- Streamline operations by maintaining a balance between supply and demand.

Restaurant inventory management software is a crucial tool that helps operators track and manage their food and beverage supplies efficiently. When integrated as part of a restaurant enterprise resource planning (ERP) system, it provides real-time insights into stock levels, ensuring that restaurant managers have accurate data on available inventory at all times.

The Restaurant Inventory Management Software, within Polaris ERP system, integrates with other business modules, such as point of sales (POS), purchase and supplier management, recipe management, or financial accounting, to offer a comprehensive approach to resource planning and facilitate efficient decision-making across the organization.

Restaurant Waste Management

According to a recent report, restaurants and food-based businesses incur losses of up to $2.6 trillion due to food waste annually. Not only is food waste costly for restaurant owners, hampering profits, but it is also impacting the environment due to its greenhouse emissions, accelerating the effects of climate change.

Restaurant waste management is the process of handling and mitigating food waste, alongside packaging, and other byproducts, with the purpose of reducing costs.

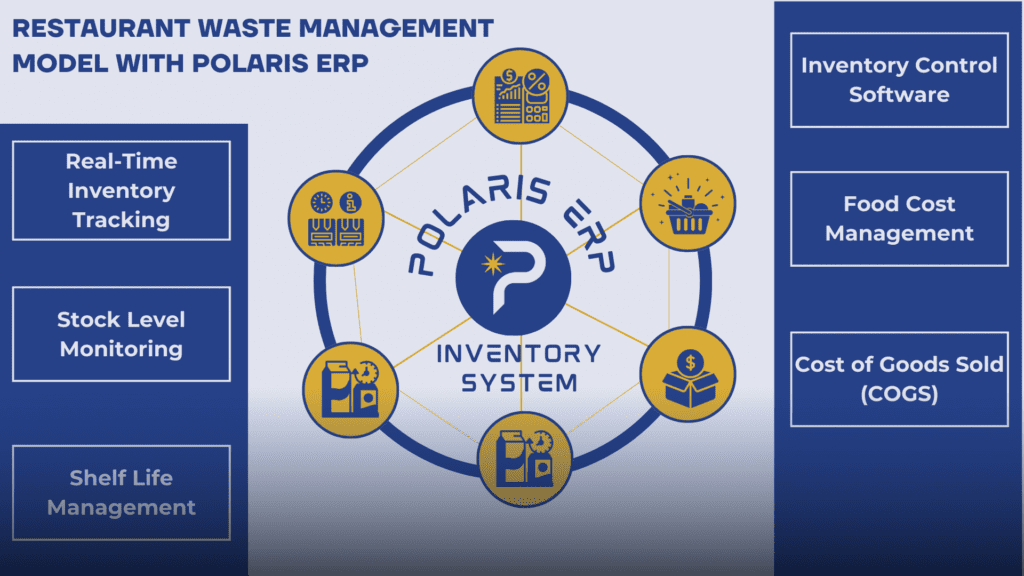

To this goal, using a restaurant inventory management software will help restaurant managers track ingredients in real time and keep optimal ingredient levels. Polaris ERP is designed to provide real-time inventory tracking, detailed sales versus expenses insights and ingredient price trends for multi-branches, while permanently communicating with purchase and supplier management system. Together, these features provide a solid foundation for waste analysis, contributing to reducing waste up to 20%.

How Can an Restaurant Inventory Management Software Help to Reduce Your Restaurant’s Waste

Inventory Control System

In the restaurant industry, it’s vital to consistently manage the availability of items and ingredients used in menu recipes. Utilizing an inventory control system becomes essential for keeping a close eye on stock levels, tracking products in real-time throughout the supply chain, and efficiently handling tasks like purchasing, shipping, receiving, warehousing, and returns. This acts as a food waste management software, informing about the condition of all items, in order to avoid spoilage and waste.

An important benefit of inventory control system is the automation of processes, which reduces human errors, allowing for real-time data analytics that enables more informed decision making for managers and owners. Furthermore, the integration of inventory control software contributes to reducing restaurant waste by optimizing inventory management and minimizing unnecessary losses.

Food Cost Management

Efficient restaurant waste management is crucial for restaurant food cost management, encompassing expenses like goods purchased, warehouse costs, and the quantity and cost of each item and ingredient used in various recipes and kitchen operations. Excessive waste poses a significant challenge to food costs, leading to increased expenses and reduced profitability.

An restaurant inventory management system proves instrumental in tackling this challenge by organizing restaurant kitchens and inventories, offering accurate information on goods through systematic categorization. From perishable items to frequently used products, the system provides insights into:

- Product expiration dates according to the first in – first out method (sending alerts when specific items need to be used or need to be replenished)

- Highlights goods that entered with higher-than-usual prices.

These comprehensive insights allow proactive measures, aiding in efficient waste reduction strategies and contributing to overall restaurant efficiency.

Cost of Goods Sold

In addition to the essential role in pricing, menu optimization, and cost control, tracking and managing the Cost of Goods Sold (COGS) plays a crucial part in waste management for restaurant owners. COGS, representing the cost incurred in selling specific menu items, covers raw materials, ingredients, and other production-related expenses.

The formula for COGS is:

COGS = Beginning Inventory + Purchases − Ending Inventory

By efficiently managing COGS through a restaurant inventory management system, restaurant owners gain insights into inventory levels, product usage, and trends. This, in turn, empowers them to minimize waste, reduce excess inventory, and adopt strategies for sustainable operations, further aligning financial success with waste reduction initiatives.

Real-Time Inventory Tracking

An efficient restaurant inventory management software provides real-time inventory tracking of available products and ingredients, or other goods in the inventory, like uniforms, or kitchen utensils for instance. This feature encompasses a complex network of downstream and upstream suppliers, interconnected in an unified system that identifies where each individual product sits across their entire life cycle.

The real-time inventory tracking feature by Polaris ERP empowers restaurant owners to proactively manage their inventory, identifying products that need to be used fast to prevent wastage. It also allows owners to monitor stock levels closely, prompting timely replenishment to avoid depletion.

This seamless integration between inventory visibility and waste reduction aligns with sustainable practices, ensuring optimal resource utilization and minimizing unnecessary waste in restaurant operations.

Stock Level Monitoring

Stock level monitoring in restaurant inventory management involves the continuous observation and assessment of the quantity of products, ingredients, and other items held in stock. The primary purpose of this monitoring is to proactively manage inventory levels to reduce waste. By keeping a close eye on stock levels, businesses can achieve the following objectives related to waste reduction: preventing overstocking, minimizing out-of-stock situations, aligning stock levels with actual demand, identifying slow-moving items or implementing FIFO method.

Shelf Life Management

Shelf Life Management in a restaurant inventory management software empowers restaurants to effectively manage the freshness and usability of products, promoting a proactive approach to waste reduction. It ensures that products are utilized efficiently, contributing to both operational efficiency and sustainability in the food service industry.

Withing Polaris ERP restaurant inventory software, shelf life management includes automated alerts, informing when products approach their expiration date. This real-time visibility empowers owners to strategically incorporate these items into various dishes promptly, minimizing the risk of spoilage and optimizing inventory utilization.

Complex Restaurant Inventory Management

For restaurant chains, establishments with multiple brands, or those operating across various branches, inventory management becomes exceptionally intricate, necessitating the adoption of an advanced restaurant inventory system. In such scenarios, a variety of factors comes into play, as outlined below.

Supplier Relationship Management (SRM)

Cultivating strong bonds with suppliers is foundational for a reliable and sustainable supply chain, crucial for both inventory management and waste reduction. SRM involves negotiating contracts, ensuring timely deliveries, and maintaining optimal stock levels. By fostering transparent and accountable relationships, Polaris ERP minimizes disruptions, enhances automated inventory control, and contributes to reducing waste through efficient supply chain practices and order management.

Multi-Location Inventory Management

For restaurant chains and franchises, consistent inventory control across multiple locations is essential for waste reduction. Multi-location restaurant inventory management focuses on creating a centralized system that synchronizes stock levels, streamlines procurement, and facilitates seamless communication between outlets. With this approach, Polaris ERP ensures uniformity, reduces excess stock, and enhances waste management practices across diverse locations.

Automated Procurement Processes

Automating procurement processes is not just about efficiency; it’s a strategic move towards minimizing restaurant waste. Automation streamlines order generation, approvals, and supplier communications, reducing human errors and expediting the procurement cycle. By incorporating technology into procurement workflows, restaurant owners can enhance accuracy, optimize costs, and contribute to waste reduction through more controlled inventory management.

Minimizing food waste in restaurant businesses remains a significant journey to saving costs and boosting profitability. The adoption of an advanced restaurant inventory management solution, equipped with food costing, automated processes and supplier management and waste analysis is the best solution to manage a restaurant business in a sustainable manner. This not only helps in reducing food waste but also curbs costs arising from spoilage, ultimately enhancing restaurants’ profitability.

Related Stories

4 Comments

Comments are closed.

[…] widespread challenge in the F&B world: minimizing waste and optimizing production expenses. Its inventory management function guides restaurateurs in efficient stock management, preventing overstocking and minimizing […]

[…] The ERP also ensures that items and quantities received match the orders placed, minimizing errors. This automation reduces the risk of human mistakes, improves efficiency, and ultimately saves both time and money by cutting down labor costs and minimizing waste. […]

[…] Restaurant Inventory Management: Save Costs and Reduce Waste […]

[…] Cost of Waste: […]